| 工作原理: | 其它 | 用途: | 其它 |

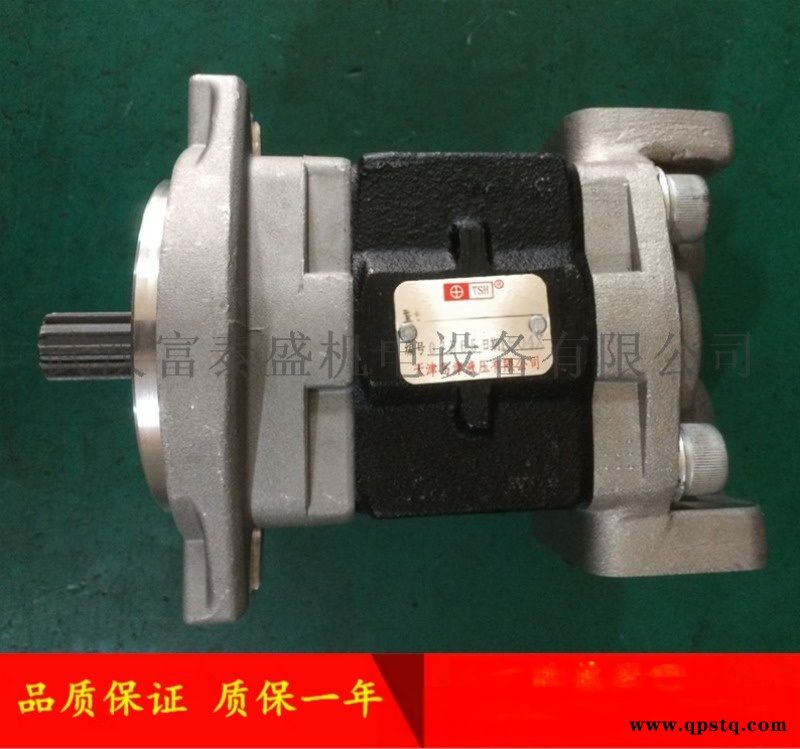

| 级数: | 其它 | 材质: | 铸铁 |

| 适用范围: | 工程机械 | 适用介质: | 液压油 |

| 适用温度(℃): | 30-90 | 公称压力(MPa): | 32MPA |

| 是否有现货: | 是 | 安装形式: | 法兰 |

| 额定流量: | 12 | 规格: | 型号 |

| 商标: | 11 | 包装: | 木箱 |

| 产量: | 888 |

--------- 力士乐三一混凝土泵车A11VLO260主油泵力士乐A10VO63LA8DS/53R-VUC12N00柱塞泵现货柱塞泵销售

-------------- 力士乐三一混凝土泵车A11VLO260主油泵力士乐旋挖钻机主油泵ALA10V045DFR1/31R-AZPF厂家直销

高压柱塞马达

规 格:A2F28、A2F45、A2F55、A2F63、A2F80、A2F107、A2F125、A2F160、A2F250

产品说明:具有固定的排量,在开式或闭式系统中作静压传动,当作马达使用时,输出转数和流量成正比而与排量成反比。

特 点:缸体与配油盘采用球面配油,在旋转中能自动对中,圆周速度较小,效率高;驱动轴能承受径向负荷;噪音低。

注意事项:1.任何场合都应保持液压油的清洁度;

2.定期更换液压油(工作1000~3000小时或六个月)。

R902067281 A11VO130LRDH1/10L-NZD12K01R902067282 A11VO130LRDH1/10L-NZD12K01-KR902067381 A11VO130LR3S/10R-NZD12K02R902068205 A11VO130LRD/10L-NSD12K02R902068360 A11VO130LRDH2+A11VO130LRDH2R902068361 A11VO130LRDH2/10R-NPD12K17R902068369 A11VO130LE2S/10R-NZD12K02T-SKR902069079 A11VO130LRDU2/10L-NSD12K02HR902069107 A11VO130DRS+A11VO130DRSR902069175 A11VO130LG1DS/10L-NZD12K02R902069278 A11VO130LRS/10L-NSD12N00R902069305 A11VO130EP2G/10R-NPD12K17HR902069306 A11VO130EP2G/10R-NSD12K04HR902069347 A11VO130/10+A11VO130/10+A11VO40DRS/10R902070015 A11VO130EP2/10L-NZD12N00HR902070016 A11VO130EP2/10L-NZD12K07HR902070182 A11VO130LRDH1/10R-NZD12K01-KR902070183 A11VO130LRDH1/10R-NZD12K01R902070285 A11VO130DRS+A10VO28DFR+A10VO28ED73R902070286 A11VO130DRS+A10VO28ED73R902071674 A11VO130EP2/10R-NPD12K02HR902071714 A11VO130DRG/10R-NSD12K04R902071783 A11VO130DRS/10R-NZD12K01R902071898 A11VO130DR+A11VO130DRR902071899 A11VO130DR/10R-NZD12K83电刷镀技术:在柱塞表面刷镀耐磨材料;氏体耐磨材料;金粉末。在缸体内壁上制备非晶态薄膜或涂层。因为缸体孔内壁有了这种特殊物质,所以才能组成硬—硬配对的磨擦副。如果盲目地研磨缸体孔,把缸体孔内壁这层表面材料研掉,磨擦 加的结构性能也就改变了。被去掉涂层的磨擦副,如果强行使用,就会磨擦面温度急剧升高,柱塞杆与缸孔发生胶合。另外在柱塞杆表面制备一种 的薄膜涂层,涂层含有减磨+耐磨+润滑功能,这组磨擦副实际还是硬涂层,也就破坏了 配对材料的磨擦副,修理这些特殊的柱塞泵,就要送到专业修理厂。滑靴与斜盘的滑动磨擦是斜盘柱塞泵三对磨擦副中 复杂的一对。表1列出柱塞杆球头与滑靴球窝的间隙腔中的高压油就会从柱塞球头与滑靴间隙中泄出。

R902039164 A4VG125HWDT1/32R-NZF02F011S-K R902039195 A4VG125HDDT1/32L-NZF02F011S *G* R902039199 A4VG125NVDT1/32L-NAF02K021E-S R902039206 A4VG125DA2D2/32R-NZX02F021S-S *G* R902039261 A4VG125HDXM1/32R-NSF02F021D-S R902039384 A4VG125HWDM1/32L-NZF02F021D R902039385 A4VG125EZ2DM1/32R-NZF02F011P *G* R902039386 A4VG125EP2DM1/32L-NZF02F021D *G* R902039392 A4VG125HDMT1/32R-NSF02F021S-S R902039431 A4VG125HWD1/32L-NZF02F001S-S R902041361 A4VG125HDXM1/32R-NSF02F021S-S R902041366 A4VG125HWD1/32R-NAF02F011S-K R902041720 A4VG125HDMT1/32R-NZF02F001S-S R902044805 A4VG125DGDT1/32R-NSF02F021S-S R902044820 A4VG125NVD1/32R-NSF02F691S R902044842 A4VG125NVD1/32R-NSF02F021D R902048085 A4VG125HDMT1/32R-NZF02F011S-S R902048144 A4VG125HDMT1/32R-NZF02F011S-SK R902048146 A4VG125DGD1/32L-NZF02F001L-S R902050154 A4VG125DWDMT1/32R-NAF02F001D-S R902050168 A4VG125DGD1/32R-NSF02F001S R902051490 A4VG125EP2D1/32L-NAF02F021LH-S R902051493 A4VG125EP2/32+A10VG18EP2/10 R902052807 A4VG125EZ2D1/32L-NZF02F001SC-S R902052909 A4VG125HWDLM1/32R-NAF02F041P-S R902052925 A4VG125HWDLM1/32R-NSF02F041P-S R902052930 A4VG125EP1DM1/32L-NSF02F001D *G* R902052933 A4VG125HWDLT1/32R-NSF02K021E-S R902052935 A4VG125EP2DM1/32R-NZF02F00XDH-S R902053063 A4VG125EZ2DM1/32R-NZF02F001FH R902053087 A4VG125EP2DT1/32L-NZF02F021D *G* R902053090 A4VG125HWD1/32L-NZF02F071S R902053091 A4VG125HW/32+A11VO60DRS/10 R902053284 A4VG125EP2DM1/32L-NSF02K07XEH-S R902053286 A4VG125EP2/32+A4VG40EP2/32 R902053318 A4VG125HDMT1/32R-NZF02F011S-SK R902053347 A4VG125EZ1DX/32R-NZF02F071FH-S R902053398 A4VG125EP2DM1/32R-NZF02F001MH-S

R902084920 A4VG125DA2D2/32L-NZF02FXX1DH-S R902085507 A4VG125HWD1/32R-NZF02F071D-S R902085522 A4VG125DA2D7/32R-NZF02F021SP R902085567 A4VG125DA1D2/32L-NZF02F021FH R902085602 A4VG125EP2D1/32L-NSF02F071SH R902085626 A4VG125EP2DT2/32L-NAF02F741SH-S R902085627 A4VG125EP2DT2/32L-NZF02F001SH-S R902085628 A4VG125EP2/32+A4VG125EP2/32 R902085629 A4VG125EP2D1/32R-NAF02F011DT-S R902085652 A4VG125HWDLM1/32L-NSF02F011S-SK R902085732 A4VG125HWD2/32R-NSF02F071K R902085736 A4VG125HD1D1/32L-NSF02N001E R902085748 A4VG125EP2D1/32R-NZF02F043LH R902085755 A4VG125EP2D1/32L-NSF02F041MH R902085796 A4VG125DA2D2/32R-NZF02K021EH 力士乐三一混凝土泵车A11VLO260主油泵力士乐中联混凝土泵车恒压泵A10VO28滑靴与斜盘油膜减薄,严重时会造成静压支承失效,滑靴与斜盘发生金属接触磨擦,滑靴烧蚀脱落,柱塞球头划伤斜盘。柱塞杆球头与滑靴球窝超出公差1.5倍时,必须成组更换之。斜盘平面被柱塞球头刮削出沟槽时,可采用激光熔敷合金粉末的方法进行修复。激光熔敷技术既可保证材料的结合强度,又能保证补熔材料的硬度,且不全降低周边组织的硬度。也顺以采用铬相焊条进行手工堆焊,补焊过的斜盘平面需重新热处理, 采用氮化炉热处理。不管采取哪种方法修复斜盘,都必须恢复原有的尺寸精度、硬度和表面粗糙度。配流盘有平面配流和球面配流两种形式。球面配流的磨擦副,在缸体配流面划痕比较浅时,通过研磨手段修复;缸体配流面沟槽较深时,应先采用“表面工程技术”手段填平沟槽后。来了隐患,也可能对柱塞泵的使用造成 的危害。污染物混入系统后会加速液压零件的磨损、研损、甚至破坏或者引起阀的动作失灵或者引起噪声。

R902084920 A4VG125DA2D2/32L-NZF02FXX1DH-S R902085507 A4VG125HWD1/32R-NZF02F071D-S R902085522 A4VG125DA2D7/32R-NZF02F021SP R902085567 A4VG125DA1D2/32L-NZF02F021FH R902085602 A4VG125EP2D1/32L-NSF02F071SH R902085626 A4VG125EP2DT2/32L-NAF02F741SH-S R902085627 A4VG125EP2DT2/32L-NZF02F001SH-S R902085628 A4VG125EP2/32+A4VG125EP2/32 R902085629 A4VG125EP2D1/32R-NAF02F011DT-S R902085652 A4VG125HWDLM1/32L-NSF02F011S-SK R902085732 A4VG125HWD2/32R-NSF02F071K R902085736 A4VG125HD1D1/32L-NSF02N001E R902085748 A4VG125EP2D1/32R-NZF02F043LH R902085755 A4VG125EP2D1/32L-NSF02F041MH R902085796 A4VG125DA2D2/32R-NZF02K021EH 力士乐三一混凝土泵车A11VLO260主油泵力士乐中联混凝土泵车恒压泵A10VO28滑靴与斜盘油膜减薄,严重时会造成静压支承失效,滑靴与斜盘发生金属接触磨擦,滑靴烧蚀脱落,柱塞球头划伤斜盘。柱塞杆球头与滑靴球窝超出公差1.5倍时,必须成组更换之。斜盘平面被柱塞球头刮削出沟槽时,可采用激光熔敷合金粉末的方法进行修复。激光熔敷技术既可保证材料的结合强度,又能保证补熔材料的硬度,且不全降低周边组织的硬度。也顺以采用铬相焊条进行手工堆焊,补焊过的斜盘平面需重新热处理, 采用氮化炉热处理。不管采取哪种方法修复斜盘,都必须恢复原有的尺寸精度、硬度和表面粗糙度。配流盘有平面配流和球面配流两种形式。球面配流的磨擦副,在缸体配流面划痕比较浅时,通过研磨手段修复;缸体配流面沟槽较深时,应先采用“表面工程技术”手段填平沟槽后。来了隐患,也可能对柱塞泵的使用造成 的危害。污染物混入系统后会加速液压零件的磨损、研损、甚至破坏或者引起阀的动作失灵或者引起噪声。

4WRA10E60-2X/G24N9K44WA10-J-G24A10VS071DFR1/32R-VPB22U99S2184A10VSO100DFR1/31R-VPA12N00A10VSO140DFR1-31R/PPB12N00A10VS071DR/31R-PSA12N00E-A10VSO100DFLR/31R-PPA12NOOA10VSO18DFR1/31R-PPC12N00A10VSO100DFR1/32R-PPB12NOO4WRA10E60-2X/G24K4A10VS0140DFRI/31R-PPB12N00A10VSO100DR/32R-VPB12N00A10VSO100DR/31R-PPA12NOOA10VS071DR/31L-PPA12N00A10VSO71DRS/32R-VPB22U99-S2184,1p4WRA10W30-2X/G24K4/V+VT-MSPA2-1-1X/V0/0A10VSO100DFR1/32R-PPB12N00A10VS028DFLR/31R-PPA12N00A10VS018DFR1/31RPPA12N00

力士乐三一掘进机A11VO95:待审核