| 工作原理: | 其它 | 用途: | 其它 |

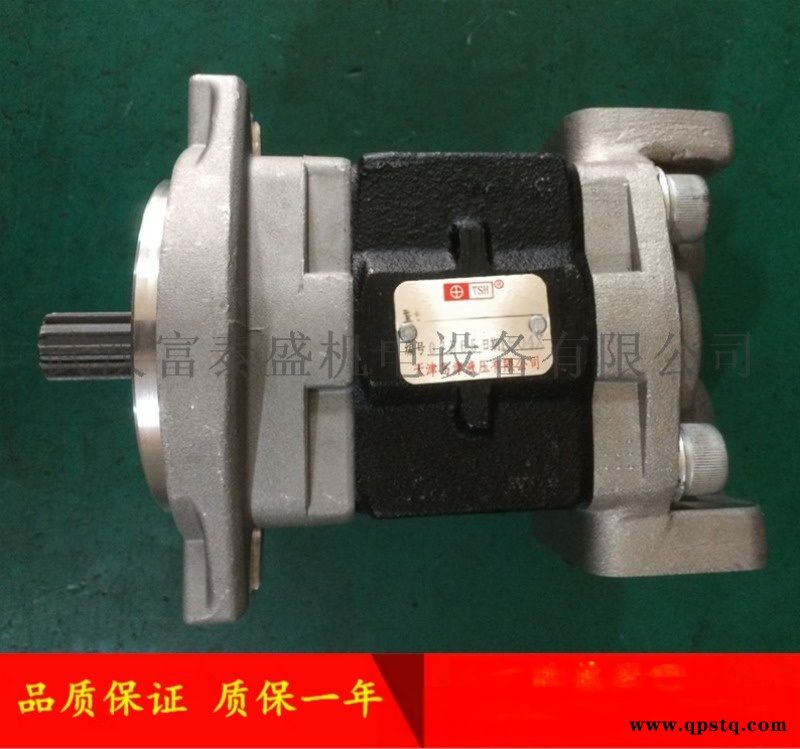

| 级数: | 其它 | 材质: | 铸铁 |

| 适用范围: | 工程机械 | 适用介质: | 液压油 |

| 适用温度(℃): | 30-90 | 公称压力(MPa): | 32MPA |

| 是否有现货: | 是 | 安装形式: | 法兰 |

| 额定流量: | 12 | 规格: | 型号 |

| 商标: | 11 | 包装: | 木箱 |

| 产量: | 888 |

--------- 大象混凝土泵车主油泵A4VG180泵,马达中联混凝土泵车A4VG140主油泵泵,马达柱塞泵销售

-------------- 大象混凝土泵车主油泵A4VG180泵,马达A4VG56EZ2DM1/32R-NSC02F003FH柱塞泵泵,马达厂家直销

高压柱塞马达

规 格:A2F28、A2F45、A2F55、A2F63、A2F80、A2F107、A2F125、A2F160、A2F250

产品说明:具有固定的排量,在开式或闭式系统中作静压传动,当作马达使用时,输出转数和流量成正比而与排量成反比。

特 点:缸体与配油盘采用球面配油,在旋转中能自动对中,圆周速度较小,效率高;驱动轴能承受径向负荷;噪音低。

注意事项:1.任何场合都应保持液压油的清洁度;

2.定期更换液压油(工作1000~3000小时或六个月)。

R902053490 A4VG125DA2D2/32L-NZF02FXX1SH-S R902053524 A4VG125EP2D1/32L-NZF02F691ST-S R902053525 A4VG125EP2D1/32L-NZF02K691ET-S R902053526 A4VG125EP2D1/32L-NZF02F021ST-S R902053527 A4VG125EP2D1/32L-NSF02F001ST-S R902053528 A4VG125EP2D1/32L-NAF02F691ST-S R902053529 A4VG125EP2DT1/32L-NSF02N001ET-S R902053530 A4VG125EP2D1/32L-NZF02F691SW-S R902053531 A4VG125EP2D1/32L-NZF02F021SW-S R902053532 A4VG125EP2D1/32L-NZF02K691EW-S R902053533 A4VG125EP2D1/32L-NZF02F001ST-S R902053534 A4VG125EP2D1/32L-NZF02K021ET-S R902053707 A4VG125DA2D2/32R-NZF02F071ST-S R902053709 A4VG125DA2D2/32L-NZF02F001SC-S R902053718 A4VG125DA2/32+A10VO71DFLR/31 *G* R902053797 A4VG125DA2/32+A10VO71DFR/31 *G* R902053883 A4VG125EP2D1/32L-NZF02F071SH R902055409 A4VG125DA1DMT4/32R-NZF02F021FH R902055410 A4VG125DA1DMT8/32R-NZF02F021DH R902055411 A4VG125DA1DM4/32R-NAF02F041SH R902055415 A4VG125DA1DM4/32R-NZF02F021SH-S R902055416 A4VG125DA1D2/32R-NZF02F011SH R902055425 A4VG125DA1D2/32R-NZF02F071SH-S 油压机径向柱塞液压马达的常见故障有:①转速下降,转速不够;②输出扭矩不够;③液压马达不转圈,不工作;④速度不稳定;⑤马达轴封处漏油(外漏)。①配流轴磨损,或者配合间隙过大以轴配流的液压马达,当配流轴磨损时,使得配流轴与相配的孔(如阀套或配流体壳孔)间隙增大,造成内泄漏增大,压力油漏往排油腔,使进人柱塞腔的流量大为减小,转速下降。此时可刷镀配流轴外圆柱面或镀硬铬修复,情况严重者需重新加工更换。②配流盘端面磨损,拉有沟槽采用配流盘的液压马达,如JMDG型、NHM型等,当配流盘端面磨损,特别是拉有较深沟槽时,内泄漏增大,使转速不够;另外,压力补偿间隙机构失灵也造成这一现象。此时应平磨或研磨配流盘端面。

R910905403 AA10VSO45DFR1/31R-PPA12N00-SO32R910903163 AA10VSO28DR/31R-PPA12N00R902474118 A4VSO180DFR1/30R+A10VSO71DR/31RR902469708 AA10VSO100DR/32R-CPB12N00R902452789 AA10VSO71DRS/32R-VPB22U99R902452707 AA10VSO45DFR1/32R-VPB12N00-S2655R902452431 AA10VSO71DRS/32R-VPB22U99-S2184R902452429 AA10VSO71DRS/32R-VPB22U99-S2183R902449982 AA10VSO100DR/32R-VPB12N00R902449060 A10VSO100DRS/32R-VPB22U99S1439BR-BEIJ-0R902449059 AA10VSO140DRS/32R-VPB22U99R902449039 A10VSO71DRS/32R-VPB22U99S2183BR-BEIJ-1R902449011 A10VSO100DRS/32R-VPB12N00S1439BR-BEIJ-1R902448219 AA10VSO140DRS/32R-VPB12N00R902439054 AA10VSO140DFR1/32*UNGUEL***R902436353 AA10VSO100DRS/32R-VPB12N00-S1439R902433059 AA10VSO71DR/31R-PPA12KB2R902428405 AA10VSO45DFR1/31R-PPA12N00-S1648

R902034932 A11VO60HD2/10R-NPC12N00-SR902036228 A11VO60DRS/10R-NSC12N00ER902036268 A11VO60HD2/10L-NZC12K01R902037034 A11VO60DRS/10R-NZC12K01-KR902037036 A11VO60DRS/10L-NZC12K01-KR902037038 A11VO60DRS/10R-NZC12K01-S大象混凝土泵车主油泵A4VG180泵,马达A4VG180DP4D1/32L-NTD02F691DP柱塞泵泵,马达油压机径向柱塞液压马达的常见故障有:①转速下降,转速不够;②输出扭矩不够;③液压马达不转圈,不工作;④速度不稳定;⑤马达轴封处漏油(外漏)。①配流轴磨损,或者配合间隙过大以轴配流的液压马达,当配流轴磨损时,使得配流轴与相配的孔(如阀套或配流体壳孔)间隙增大,造成内泄漏增大,压力油漏往排油腔,使进人柱塞腔的流量大为减小,转速下降。此时可刷镀配流轴外圆柱面或镀硬铬修复,情况严重者需重新加工更换。②配流盘端面磨损,拉有沟槽采用配流盘的液压马达,如JMDG型、NHM型等,当配流盘端面磨损,特别是拉有较深沟槽时,内泄漏增大,使转速不够;另外,压力补偿间隙机构失灵也造成这一现象。此时应平磨或研磨配流盘端面。

R902034932 A11VO60HD2/10R-NPC12N00-SR902036228 A11VO60DRS/10R-NSC12N00ER902036268 A11VO60HD2/10L-NZC12K01R902037034 A11VO60DRS/10R-NZC12K01-KR902037036 A11VO60DRS/10L-NZC12K01-KR902037038 A11VO60DRS/10R-NZC12K01-S大象混凝土泵车主油泵A4VG180泵,马达A4VG180DP4D1/32L-NTD02F691DP柱塞泵泵,马达油压机径向柱塞液压马达的常见故障有:①转速下降,转速不够;②输出扭矩不够;③液压马达不转圈,不工作;④速度不稳定;⑤马达轴封处漏油(外漏)。①配流轴磨损,或者配合间隙过大以轴配流的液压马达,当配流轴磨损时,使得配流轴与相配的孔(如阀套或配流体壳孔)间隙增大,造成内泄漏增大,压力油漏往排油腔,使进人柱塞腔的流量大为减小,转速下降。此时可刷镀配流轴外圆柱面或镀硬铬修复,情况严重者需重新加工更换。②配流盘端面磨损,拉有沟槽采用配流盘的液压马达,如JMDG型、NHM型等,当配流盘端面磨损,特别是拉有较深沟槽时,内泄漏增大,使转速不够;另外,压力补偿间隙机构失灵也造成这一现象。此时应平磨或研磨配流盘端面。

R909604294 A6VM55DA1/63W-VZB017BR909604305 A6VM55HD1/63W-VZB017BR909604385 A6VM55HA1TX/63W-VZB027A-SR909604517 A6VM55HZ3/63W-VZB020BR909604523 A6VM55EZ3/63W-VZB020HBR909604537 A6VM55HA3T/63W-VZB020AR909604574 A6VM55HD1D/63W-VZB020BR909604588 A6VM55EZ3/63W-VAB020BR909604598 A6VM55HD1/63W-VAB020BR909604646 A6VM55EP2D/63W-VZB020BR909604759 A6VM55HZ3/63W-VZB017BR909604811 A6VM55EZ3/63W-VZB027BR909604853 A6VM55HD1D/63W-XZB010B-SR909604881 A6VM55HA1T/63W-VZB010AR909604898 A6VM55HZ3/63W-VZB010BR909610520 A6VM55HA1T/63W-VAB380AR909610563 A6VM55HA2T/63W-VZB027AR909610705 A6VM55HA1/63W-VAB020AR909610706 A6VM55HA1U2/63W-VAB020AR909610708 A6VM55DA1/63W-VAB020B

大象混凝土泵车主油泵A4VG125泵,马达:待审核